- Dispatching

- Automation

- Modernization

- IT technologies

DISPATCHING — automated centralized operational control and management of technological processes in residential buildings, energy, industrial and other enterprises. It is based on remote or local transmission of information to the central dispatching point. Remote control using operational transmission of information between dispatching objects and the control point.

Goals and objectives:

Types of automated data collection and management

Local dispatching (Automation)

A closed system that transmits process data from one or more engineering systems to the operator's computer, with the control center located within the same building.

Remote dispatching

Integrates one or more automated (local) systems and uses various data transmission channels to transmit parameters from geographically remote facilities to the central dispatching station.

A local system may include several subsystems:

Data collection and processing in a remote dispatch system is carried out using programmable controllers that support various data transfer standards. Controllers can operate in two modes: dependent (together with the CPU) and independent (in the absence of external control). Remote dispatch can combine several objects, where data collection and control are carried out by an automated (local) control system.

AUTOMATION — process of introducing automatic equipment and automated complexes that perform control and management functions into production.

Automation options:

MODERNIZATION — change in existing technologies and equipment in order to improve the operational parameters of production, eliminate wear and tear of mechanisms and obsolescence of processes, and bring them into line with new requirements.

Modernization includes:

IT TECHNOLOGY – creation of software for unique production needs.

You get:

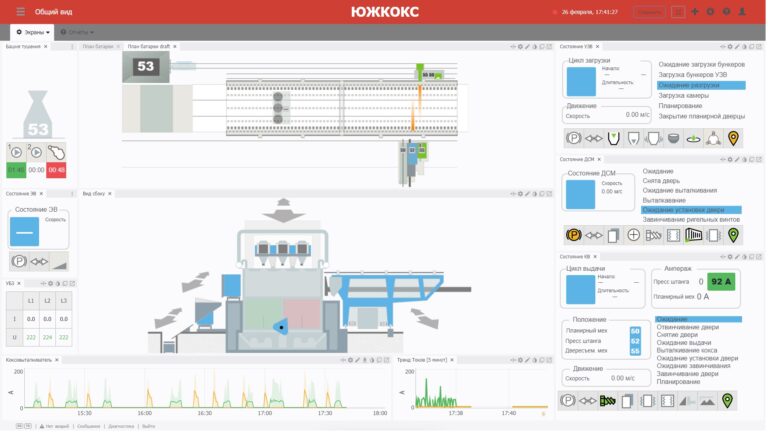

Monitoring, dispatching and automation solutions based on modern distributed systems

1. Modernization of existing automation systems based on industrial PLCs to meet Industry 4.0 standards

The ability to retrofit existing automation systems (without replacing equipment and software) with integration controllers that ensure their integration into a single information system, allowing: to exchange data, export them directly to the MES, ERP software, build reports, flexible and complete visualization, information, control.

2. Creation of new "turnkey" automation systems - automation systems for technological processes taking into account PLCs, corresponding to Industry 4.0.

Our solutions combine the reliability and speed of technological process control using PLCs with the capabilities of data collection, visualization, remote monitoring and management via the web, as well as integration with any enterprise information systems. Our concept provides easy integration of classic industrial automation systems with modern technologies such as RFID identification systems, LoRa wireless data collection systems, precise positioning on the ground for GPS RTK motion control systems, etc.

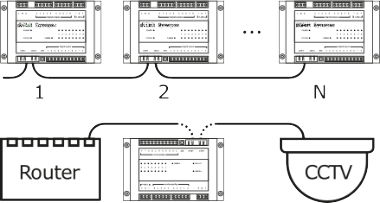

3. Building a distributed architecture of intersystem interaction

4. Building systems for analyzing resource costs

5. Using wireless autonomous long-range data collection systems with ultra-low power consumption

6. Using individual integrated positioning, video recording, communication, etc. tools in personnel management systems to optimize production processes and improve labor safety.

We conduct informational and educational webinars with automation specialists, demonstrating key capabilities using the example of a small project.

Our company has been successfully developing and implementing solutions in the field of industrial automation, dispatching, control, and data collection systems for many years, based on its own original devices and systems, covering the entire spectrum of tasks from the lowest level to cloud systems.

Product example

FlexHMI controller - device description

FlexHMI communication controller is a ready-made hardware and software complex with a built-in SCADA system for building data acquisition, visualization and control systems. It allows you to collect data from ACS devices using standard industrial protocols, provides their processing, storage and creation of a user interface. Due to the built-in scripting language, it is possible to implement logical operations and simple equipment control algorithms even without the use of industrial PLCs.

Key features of FlexHMI

• Built-in free SCADA system for visualization and control, without restrictions on the number of tags

• Work with equipment of any brands that support standard industrial exchange protocols, including the MQTT protocol for integration with IoT (Internet of Things) (Firmware 4.0)

• Ability to implement non-standard exchange protocols with various equipment within the device

• Local or remote access to the system via a regular WEB browser, password protection, protection via VPN

• Implementation of notifications via SMS, Viber, Telegram

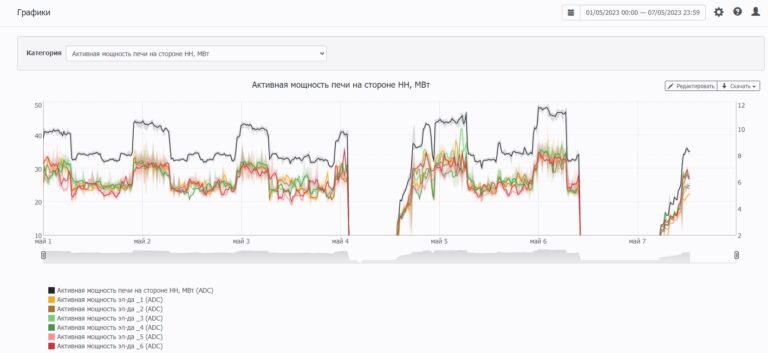

• Starting from firmware 4.0 — built-in components for visualization and data analysis — Gantt Chart, Radar Chart, Pie Chart, Line Chart, Column Chart

• Set of interfaces - 2xEthernet, RS485, USB, Wi-Fi, data storage on an SD card up to 32 GB

The device is compatible with a wide range of equipment: controllers, frequency converters, distributed peripheral modules (DPM), various heat and electricity meters, etc., Aries, Mbus, NIK (OBIS codes) and others.

FlexHMI already contains everything you need and is completely ready to work. The system has no restrictions on the number of registers, users, software modules, additional licenses or other hidden costs that integrators need to take into account at the design stage. Development tools are integrated directly into the device firmware. The purchase of any additional software for implementing a project based on FlexHMI is not required. The operator interface uses a built-in SCADA system, which allows you to visualize almost any technological process.

All work with the device - project settings, as well as control system interfaces (mnemonics, reports, graphs) for the operator are implemented by accessing FlexHMI through a regular web browser window. Thus, there are no specific requirements for the operator's workstation - it can be any relatively modern PC, with any OS, as well as a tablet PC or smartphone.

Data (with the ability to individually configure each register) is stored in a local database on the device, on an industrial SD memory card with a capacity of up to 32 GB (purchased separately, depending on the required volume). FlexHMI allows integration with other systems as a gateway - all data collected by it can be accessed by other systems via the Modbus TCP protocol, as well as via API.

At the hardware level, FlexHMI is an ultra-compact single-board computer. It has several network interfaces: 2 Ethernet ports, Wi-Fi, 1 RS-485 communication port, as well as one USB port, which allows you to connect, for example, a 3G modem or an additional communication adapter to the device. (All communication ports are galvanically isolated.) If necessary, the number of USB ports can be increased using a USB hub. The device is powered by a standard industrial 24V source. FlexHMI also has a built-in high-precision real-time clock and an uninterruptible power supply.

In terms of network capabilities, FlexHMI corresponds to an industrial router. It provides the ability to route packets, filter traffic in the firewall, DNS, NAT, synchronize time using NTP, VPN client, etc. If necessary, FlexHMI can be easily connected to the Internet using any convenient commercial USB 3G modem.

The main purpose of FlexHMI:

• creation of a remote multi-user operator interface for facility or machine-building plant control systems without the use of additional SCADA systems and operator panels;

• creation of monitoring, dispatching and control systems for one or a group of distributed facilities;

• duplication of the top-level SCADA system at responsible facilities;

• creation of control and monitoring systems for simple facilities without the use of PLCs at all;

• creation of systems such as "Smart Home", "Smart House", etc., using components of the "Internet of Things" IoT system

The FlexHMI controller contains the necessary set of interfaces for integration into an existing or designed control system based on typical automation equipment - controllers, frequency converters, soft starters, meters, flow meters, input/output modules, microprocessor relay protection. It is possible to display video received from IP cameras in the operator window. At the hardware level, FlexHMI is an ultra-compact single-board computer. At the protocol level, FlexHMI supports Modbus TCP/RTU/ASCII, ISO TCP Siemens, PPI, Allen Bradley DF1, Aries, Mbus, NIK (OBIS codes), MQTT etc.

On board FlexHMI has:

• RS485 (multi-protocol), allows you to exchange data simultaneously with a group of devices with different exchange protocols and different exchange speeds;

• 2 Ethernet ports (2 independent network cards). In terms of network capabilities, FlexHMI corresponds to an industrial router. It provides the ability to route packets, filter traffic in the firewall, DNS, NAT, synchronize NTP time, VPN client, etc. It can also be used as a Wi-Fi router;

• High-precision real-time clock;

• SD card slot with a capacity of up to 32 GB for storing current project data and archiving data for plotting graphs, etc.

• Wi-Fi with the ability to simultaneously access FlexHMI and access the Internet or local network. The basic removable antenna can be replaced with a more powerful external one;

• USB port with the ability to briefly remove the power supply (to reboot modems that have fallen asleep or hung up). Allows you to connect various converters and peripherals, as well as modems to provide mobile Internet at the facility.

The firmware supports common modems of GSM operators;

• On-board uninterruptible power supply unit based on a lithium-polymer battery. Depending on the interfaces used, it can provide FlexHMI operation without external power for up to 2 hours;

• 2 solid-state relays with normally open contacts 220V 0.1A.

• All communication ports have galvanic isolation and overvoltage protection.

• The device is powered from a standard 24V source.

The FlexHMI controller already contains all the necessary software, ready to work right out of the box when installing an SD card (purchased separately) and applying power. Development tools are integrated directly into the device firmware. The purchase of any additional software for implementing a project based on FlexHMI is not required. The operator interface uses a built-in SCADA system, which allows you to visualize almost any technological process.

All work with the device - initialization of registers, project creation, as well as control system interfaces (mnemonics, reports, graphs, diagrams) are implemented by accessing FlexHMI through a regular web browser window. Thus, there are no specific requirements for the operator's workstation - it can be any relatively modern PC, with any OS, as well as a tablet PC or smartphone.

Data is stored in a local database on the device, on an industrial SD standard memory card with a capacity of up to 32 GB. FlexHMI allows integration with other systems as a gateway - all data collected by it can be made available to other systems via Modbus TCP protocol, as well as via API.

Functional features of FlexHMI:

• Multi-brand! FlexHMI is not tied to any brand of automation equipment manufacturer, i.e. the solution is universal and can be used with equipment of any brands that support standard industrial exchange protocols. For exchange with devices that have non-standard exchange protocols, it is possible to implement a user protocol using a scripting language;

• The ability to simultaneously access the system of a large number of users located in different parts of the world. Each user can use their part of the operator interface, designed as a separate window, without interfering with each other;

• The ability to remotely edit the project without visiting the facility if you have a password with administrator rights;

• Built-in SCADA system with support for external images, GIF animation, trends, graphs, charts, events, video from IP cameras;

• The built-in SCADA system has no software restrictions on the number of users, the number of registers and the number of connected devices. No licensing required!

• Built-in scripting language. It has the functionality of a simple programming language and allows you to implement user logic with data accessed by FlexHMI (calculation by formulas, logical operations, sending SMS and Viber messages, PID and PWM regulators, implementation of individual exchange protocols, control using recipes, etc.);

• Built-in WEB server for access to FlexHMI from any WEB browser. The operating system of the operator's workstation does not matter, it is Windows, Linux, Android, iOS, etc.

• Protection of access to the system using individual passwords with the ability to distinguish rights. Support for VPN services;

• Ability to remotely reprogram PLCs and other equipment installed on facilities through specialized software utilities from manufacturers;

• Data exchange with other applications via API (it is possible to provide data exchange with Android and iOS applications, 1C, office programs for reporting, etc.);

• The ability to register a set of FlexHMI in a specialized cloud service of the manufacturer Level2 for very fast and efficient construction of a dispatching system for a set of distributed objects, with advanced analytics on consumed energy resources;

• Using FlexHMI in projects does not require highly qualified personnel. Setting up and working with FlexHMI resembles the configuration process, not programming. Accordingly, programmers with knowledge of programming languages, etc. are not required.

Industrial Distributed I/O Module Phalaenopsis.Pro Neuron S1

Industrial module Neuron S1 – manufactured under the Phalaenopsis.Pro brand, is designed for remote collection of discrete signals, temperature sensors with 1Wire interface and load control and is used in dispatching and automation systems in aggressive industrial environments. The module has 2 Ethernet interfaces on board (operating in "bridge" mode) for inclusion in a local network. Communication with the module is carried out using the Neuron S1 TCP protocol. Structurally, the module is made in the form of a housing for mounting on a DIN – profile (35 mm).

Spheres of application

Building management, HVAC, heating stations

• Monitoring of production lines and machines

• Greenhouses

• Various monitoring and automation systems

The module has 8 discrete inputs (also with a counter function) for monitoring the equipment status and 8 relays for control.

Discrete inputs

• 8 bidirectional inputs with 24V level and one common point

• The module has a 24V source to power the inputs.

• Built-in digital filter

• Each input can be used as a counter (max. frequency 1 kHz.)

Discrete outputs

• 8 outputs, two groups of 4 relays

• Load capacity 5A

• Counter function for each output

In production monitoring systems, it is very often necessary to assess not only the condition of equipment, for example, machine tools, but also their productivity, resource and material consumption, which is easiest to do using a simple rotation sensor or proximity sensor and counting pulses from it. Another task is to assess the voltage of mechanisms for timely preventive maintenance or repair. Our module has everything you need for this, because each discrete channel has such functions.

Accounting functions

• Counting the number of operations (imp. kWh)

• Counting the duration of stay in the state (motor hours)

• The counters have a bit capacity of 32 bits, the values are stored in the independent memory of the device.

• Digital filters at the inputs guarantee error-free counting

• The maximum pulse frequency is 1 kHz.

Connecting an Ethernet device to a network requires a free slot in a router, switch, or second adapter in a computer. If there are no free ports at the installation location, you will need to configure additional equipment. But not in the case of the Synapse module, because it has an on-board 2-port switch operating in "bridge" mode, so the module can be installed almost anywhere in the existing infrastructure.

• Number of Ethernet ports – 2 pcs.

• Port operation mode: “most”

• Cable length on any port – 100 m.

• Speed – 100 Mbps.

Features of the 1Wire interface of the Neuron S1 module

Sensors with 1Wire interface are today the most advantageous solution for measuring temperatures in the climatic range (-40 + 85°). It should be noted that sensors of this type are quite sensitive to electromagnetic interference on the communication line, but the Synapse module uses a specialized line driver configured for the worst-case scenario when many sensors are connected, or a long cable is used.

• 3-wire "active" sensor power supply circuit (5V), with short circuit protection

• Maximum number of sensors – 32

• Maximum length of communication cable – 200 m.

• Driver restart capability

• Automatic search for sensors by hardware addresses and saving their order in non-volatile memory

Industrial caching gateway

Phalaenopsis.Pro Neurolink M1

Neurolink M1 – is an industrial caching gateway with the Neurolink TCP protocol in Neurolink RTU, operating in aggressive environments of industrial enterprises. Unlike many other gateways that only transmit packets from one network to another and back, Neurolink M1 works as an independent server that periodically reads the necessary data from devices via the RS-485 bus and returns them via Neurolink TCP. Thus, a conventional gateway only provides connection of devices with a serial interface to the control system using Ethernet, and Neurolink M1 allows you to significantly speed up the process of data collection in systems with a large number of registers and devices using low-speed fieldbus connections.

How does it work? Neurolink M1 works completely transparently. Having received a request to read TCP registers, it reads data from devices via the RS-485 bus into its internal memory (cache) and responds to the request with them. Then the gateway continues to read and update these registers in memory for a certain period, responding to requests with data from the cache. Thus, the data access time via Neurolink TCP does not depend on the scan time from the RS-485 bus side.

ModbusTCP GPS tracker, NTP server

This device is an innovative and multifunctional device that combines the capabilities of a GPS tracker and an NTP (Network Time Protocol) server. This device provides convenience and efficiency by integrating two key functions in one compact and versatile device.

The GPS tracking system allows you to track the geographical position and movement of an object in real time. By connecting to the GPS network, the device is able to determine the coordinates, altitude and speed of the object. This function is widely used in various industries, ranging from vehicles and logistics to tracking mobile resources and personnel.

However, the device is not limited to GPS tracking. It also includes the functionality of an NTP server. An NTP server is used to synchronize time between different devices on the network. This is very important in many information technologies, where accurate time synchronization is necessary for the correct operation of systems and applications. A device that acts as an NTP server ensures accurate and reliable time distribution on the network, which is important for coordinating operations and ensuring data integrity.

The integration of ModbusTCP protocol into this device complements its functionality, providing the possibility of simple and effective interaction with other devices and systems that support this protocol.

Thus, the device, which combines a GPS tracker and an NTP server, is a powerful tool for tracking and coordinating objects, as well as for ensuring accurate time synchronization in the network. Its multifunctionality makes it an attractive solution for a wide range of use scenarios in various industries and applications.

Characteristics:

GPS receiver with support for QZSS and SBAS differential correction systems, including WAAS, EGNOS, GAGAN, MSAS

22 tracking channels, 66 acquisition channels, up to 210 pseudo-random sequence code channels

Coordinate update frequency: up to 5 Гц

Meals (one of three options):

1. Micro USB 5В

2. Screw connector 7-52В

3. Passive PoE 7-52В

Data port:

Ethernet (Modbus TCP)

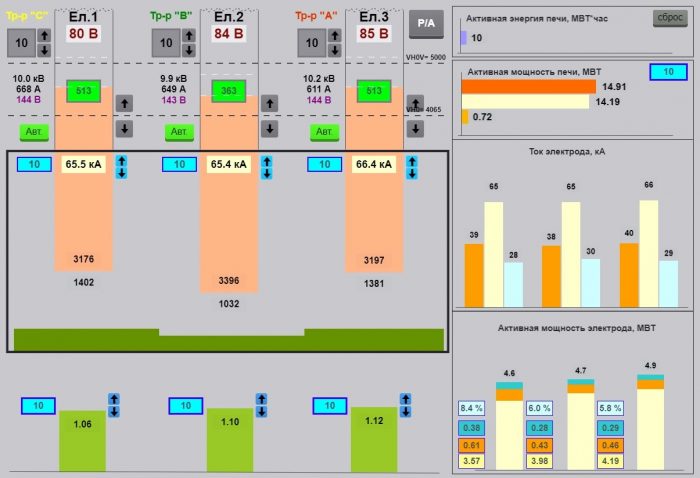

Measuring and computing controller KVEP-16

KVEPP-16 is implemented on the basis of a modern, powerful dual-core processor using a high-speed 16-channel ADC. Its distinctive feature from standard three-phase alternating current measurement systems is:

- Real-time control of traditional electrical parameters (current, voltage, power, etc. both on the high and low sides);

the possibility of using them as electrode current sensors on the low-voltage side of Rogowski belt furnaces to obtain real electrode current values;

- taking into account the specifics of electrode voltage measurement, characteristic of rectangular six-electrode CPF furnaces, the effect of the influence of currents of neighboring phases on the measured electrode voltage, by correcting the measured voltage taking into account the amplitudes and shift angles of currents of neighboring phases, in order to determine the real electrode voltage, active resistance and power;

- Determination of three components of the active resistance of the electrode (arc resistance, shunt, melt), which gives technologists an expanded idea of the processes occurring in the electrode space of the furnace.

The use of KVEPP-16 allows you to obtain at the output more than 25 basic and more than 20 additional parameters that characterize the electrical mode of the furnace, while eliminating the need to purchase expensive current, voltage, active power converters that require annual calibration.